Click here to see a case study of a 2,732 square foot residence. Click here to see a case study of a 2,732 square foot residence.

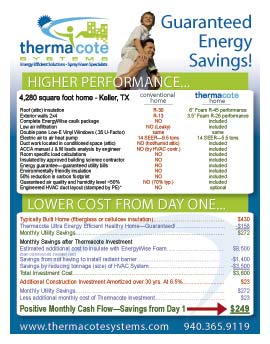

Click here to see a case study of a 4,280 square foot residence. Click here to see a case study of a 4,280 square foot residence.

|

Benefits For Commercial & Residential Applications

- Energy efficiency to maximize your return on investment: SPF is more expensive than conventional forms of insulation, but by utilizing energywiseä engineering and obtaining the Energy Cost Savings Guarantee by Bayer MaterialScience, you can reduce energy consumption as much as 70% compared to conventionally built structures. SPF will pay for itself in a very short time period, and you realize savings from ever increasing energy costs for the lifetime of your structure. Operating costs are typically cash flow positive day one for a new home. Lower energy usage is better for you and for the global environment by reducing the need for fossil fuels.

- Greater comfort for your home or work environment: Because SPF is an air barrier, air infiltration and drafts are eliminated making the occupied space more evenly temperature controlled.

- Initial construction costs can be reduced: For example, Lower HVAC (Heating, Ventilation, Air Conditioning) requirements on new construction means saving dollars without loss of comfort. Because SPF provides a complete, seamless envelope around the building to protect the living or working environment from air infiltration, drafts and unwanted humidity, new construction can reduce HVAC tonnage by up to 50%. Traditionally, HVAC installers have used about 1 ton of HVAC per 500 square feet of living space. By using spray foam insulation, HVAC tonnage can be reduced to about 1 ton per 750 - 1,000 square feet. That is up to a 50% savings on the initial construction cost of HVAC. Builders also do not need to use radiant barrier or attic ventilation saving upfront construction costs.

- Spray Polyurethane Foam offers high R-value: Click here for link to technical datasheet information

- SPF contains no ozone depleting chemicals, no CFC, no HCFC, no formaldehyde, and no asbestos. Once SPF has fully cured, it does not emit any toxic vapors.

- SPF is a “stable” insulation: the aged R-value does not diminish over time. Conventional forms of insulation settle and compact and deteriorate or decompose over time significantly reducing the R-value. This type of wear will not occur with SPF. This will reduce your total cost of ownership because additional insulation will not need to be added in the future.

- Healthier indoor air quality: SPF can significantly reduce allergens, pollens, dust and odors from outdoor air infiltration to help produce a better indoor air environment. Additionally, SPF helps reduce mold, mildew and fungi.

- Quieter buildings: the semi-rigid open cell mass created by SPF absorbs and reduces unwanted sound transmission such as noisy plumbing in walls, outside railroads, aircraft, loud music or noisy neighbors. Foam insulation is ideal for media rooms and music studios. Closed cell foam insulation can eliminate any drumming effect, especially on metal buildings because of the increased strength and rigidity to the substrate.

- Reduces moisture related problems: Moisture and moisture vapor are often referred to as the number one enemy for houses and buildings. By creating the air barrier (open cell) or vapor retarder (closed cell), SPF eliminates the transfer of moist air which then prevents mold, mildew, and fungi. SPF also prevents condensation or sweating on metal roofs and buildings which also eliminates corrosion and rusting problems. SPF will not sag or drop over time and has excellent adhesion to substrates.

- Significantly reduce heat radiation on metal substrates so SPF is ideal for workshops, barns, sheds.

- Resists bugs and insects: SPF seals cracks and crevices, foam insulation helps keep unwanted creatures out and has no food value for ants, spiders, rodents, or termites. No component of SPF is a food source for insects.

- Closed cell foam adds structural integrity and increased rack strength: no damage in sustained winds of 90 mph for 60 minutes and gusts of 160 mph. Closed cell foam can add increased rack strength of 400%.

- Class I building material (same classification as other insulations) with a flame spread index rating below 25 and a smoke development index rating below 450 (ASTM E84).

Top of Page

|